Flexible ceramics?

Generally speaking, ceramics cannot be bent. If you try to bend them, they tend to break. However, ceramic materials have great advantages in that they are durable at high temperatures and chemically stable. Furthermore, they have various applications: superconductors, transparent conductors, semiconductors, dielectrics, piezoelectrics, etc. They are used in various electrical appliances such as in mobile phones, as sensors, displays, internal electronic devices etc.

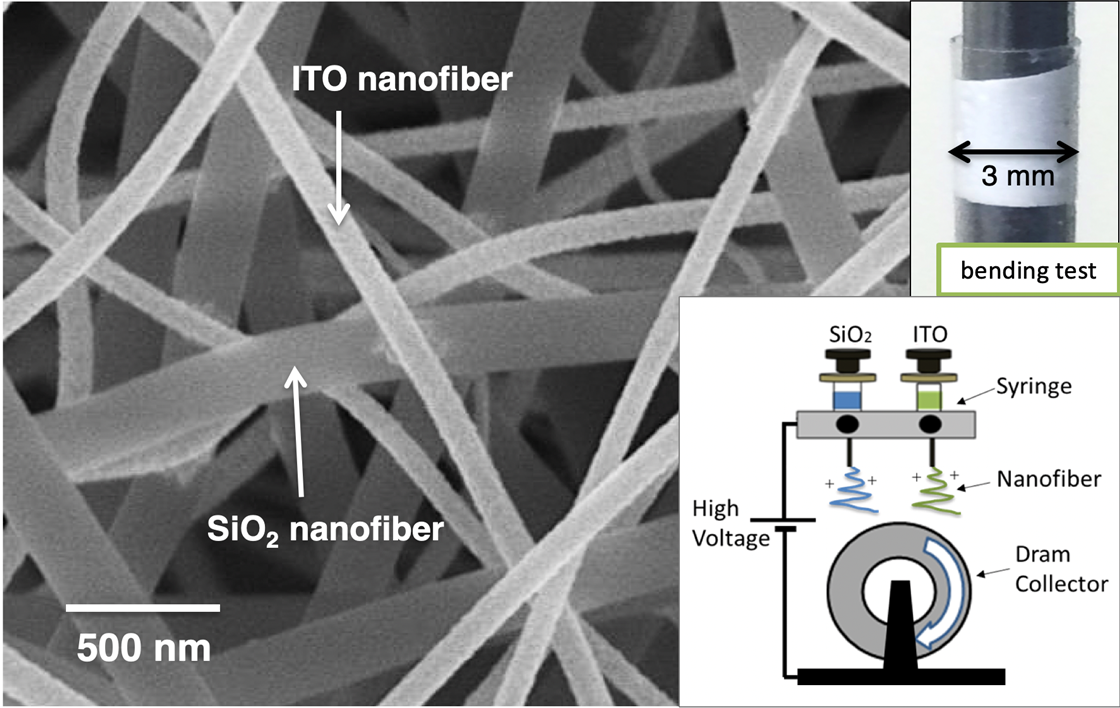

Figure 1 shows the ceramic non-woven cloth made of very thin nanoscale ceramic fibers (*1). This cloth was made using an electrospinning method. In this method, a syringe is filled with a solution of raw materials which are pulled by a high electrical field from the end of the needle, and sintered at high temperatures of 400-700 C. In the figure, two kinds of nanofiber (*2) are wound on a rotating drum collector, and non-woven cloth which consists of two different kinds of ceramic nanofibers can be prepared. Here, tin doped indium oxide (ITO) and silica (*3)(SiO2) were used for the material, and the cloth did not show any cracks even when the cloth was wound on a 3 mm diameter pole.

Various ceramic nanofibers and their application to solar cells and batteries

Many kinds of electronic devices can be produced through the combination of ceramics that have plenty of variety. ITO is a transparent conductor (*4) used for liquid crystal displays, and silica is a base material in optical fibers. Thus, flexible but flame-proof cloth which can transmit both light and electricity are created by the combination of nanofibers using these materials.

Figure 2 shows another type of nanofiber in which the surface of a "core" nanofiber is covered by another ceramics. Here, a different solution is added to the core solution, and pulled simultaneously with a strong electrical field. The core is ITO, an electrical conductor, and the sheath is tungsten oxide which is capable of storing lithium ions (*5) inside. Thus, a nanoscale co-axial battery can be produced. Our goal is the production of flexible solar cells and photorechargeable batteries (*6) which can store electricity generated from the irradiation of sunlight.

Furthermore, it will be possible to develop novel electronic devices using the flame-proof cloth that combines various ceramic materials.

*1 One nanometer is one thousand millionth of a meter, which is about ten times of the size of an atom. Nanoscale is a size that can be measured in nanometers and is less than one micron.

*2 Fibers with a nanoscale diameter. The thickness of the fibers in the photo is around 100 nm which is about one thousandth of a hair.

*3 Silicon oxide, the main material of glass

*4 Transparent but conductive material. Generally, metals which can conduct electricity absorb and reflect light, and cannot transmit light. However, some ceramics can do both.

*5 Lithium ion batteries, one of the main kinds of battery, create charge and discharge by moving lithium ions between positive and negative electrodes.

*6 By adding the function of photoelectric conversion to batteries, it’s possible to produce storage devices charged by sunlight. Solar cells cannot produce electricity at night, however, this type of battery can supply electricity stored during the daytime.