Countermeasures against vibration in automatic transmission.

Automotive transmission operates by transmitting the power generated by the engine to the wheels appropriately according to the speed of the car and the road conditions. Manual transmission (MT) and automatic transmission (AT) are the main types of transmission, but most of the cars sold in Japan now have AT. AT automatically controls the reduction ratio, and typically consists of a torque converter and a gear train with planetary gears. The torque converter transmits the power from the engine to the gear train, and the gear train changes the speed. Improvements in ride comfort and fuel economy performance are essential for today's cars, and the structure and speed control of AT has become more complicated. Along with this, the vibration characteristics of AT have become more complicated, and various vibration problems are common. In our laboratory, we study the mechanisms which generate vibrations in AT, and are investigating prevention / reduction measures.

Countermeasures against vibration caused by vibration histories

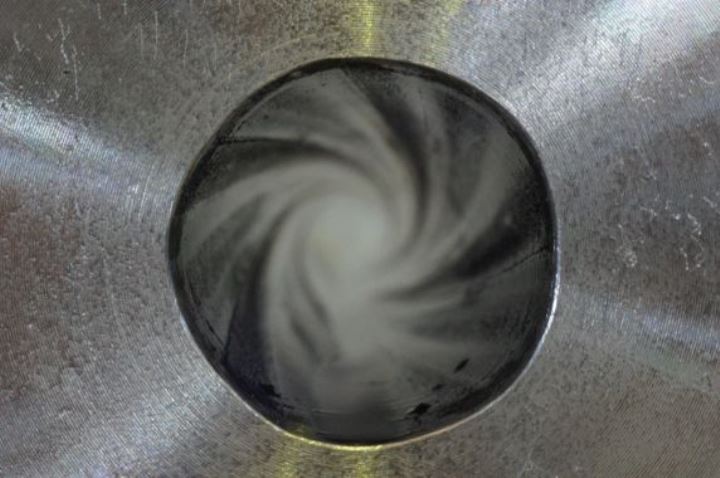

Cylindrical surfaces that rotate while touching something, such as automobile tires or rollers in steelmaking machines, may deform into polygonal shapes due to uneven wear. Likewise, during machining such as drilling and cutting, the borehole may become polygonal, or chatter marks may be generated on the surface of the workpiece. These vibration phenomena are caused by a history of vibrations building up on the surface of cylinders and workpieces. In our laboratory, we seek to clarify the generating mechanism behind these phenomena and consider preventive measures based on our findings.